FabLab Tulsa opened its doors to the public on September 13, 2011 for their grand opening celebration.

Fab Lab is short for Fabrication Laboratory. It is a community workspace providing access to an array of computer-controlled fabrication technology such as 3D Printers and Laser Cutters that can be used to conceptualize, design, develop, and fabricate almost anything.

Fab Lab is short for Fabrication Laboratory. It is a community workspace providing access to an array of computer-controlled fabrication technology such as 3D Printers and Laser Cutters that can be used to conceptualize, design, develop, and fabricate almost anything.

“You walk in with an idea, and you walk out with an idea in your hand,” said Matthew Norris, board president of Fab Lab Tulsa Inc.

Among the attendees at the grand opening were members from the Tulsa Metro Chamber, the, Hardesty Family Foundation, and EngATech CEO, Clay Slaton. EngATech is one of the many sponsors and is responsible for donating FabLab’s key piece of equipment, the Objet 3D Printing system, shown above.

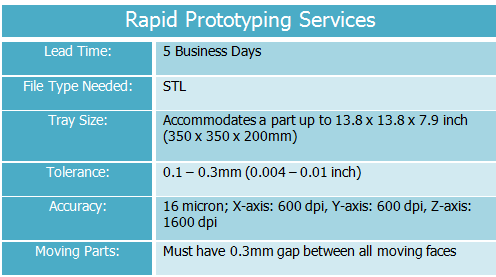

“The lab’s centerpiece will be the 3D printer, which may be the sole item in the lab with an associated fee to use,” said Norris. This relatively new technology “prints” layers of plastic one at a time, eventually building a three-dimensional object.”

Also available at FabLab Tulsa is a laser cutter, a vinyl cutter, a circuit board, an electronics workbench, a computer-guided drill station and a SolidWorks 3D CAD workstation.

During the grand opening ceremony key sponsors where ask to talk briefly about their partnership with FabLab Tulsa, where the industry is going, and what the fabrication labortory means to the Tulsa community.

“We are a product development firm, and “we help others make better products and faster”. We have had our office downtown for the past 12 years with continued growth, and one of our sayings is “From Struggling to Stable to Successful to Significant”. Meaning we want to be in a position where we can give back more and more, and are excited about our relationship with FabLab and being able to help them reach a level of true significance in the community. We chose to partner with FabLab Tulsa to donate SolidWorks 3D CAD software, and an Objet 3D Printer; so that they can now help others make products, spurring on the entrepreneurial spirit we have growing here in Tulsa,” said Slaton.

Read the full story on our website.

Visit FabLab Tulsa’s website for more information. http://www.fablabtulsa.com/